There are various things that you cannot ignore in case you want the success of something. For example, if you are in the PCB industry, it is necessary to consider PCB inspection. Doing this can help you to uncover things that you cannot do on your own. It is painful to purchase a product that is perfect in shape and ends up finding a lot of defects being associated with it. For the process, you require to hire an expert to do it.

Selecting the right method to do the process is the number one critical thing that you are requested to consider. The chances are high that you are not going to get the right condition of your boards once you pick out the wrong method. There are several techniques that you can utilize to help you identify the quality of your boards.

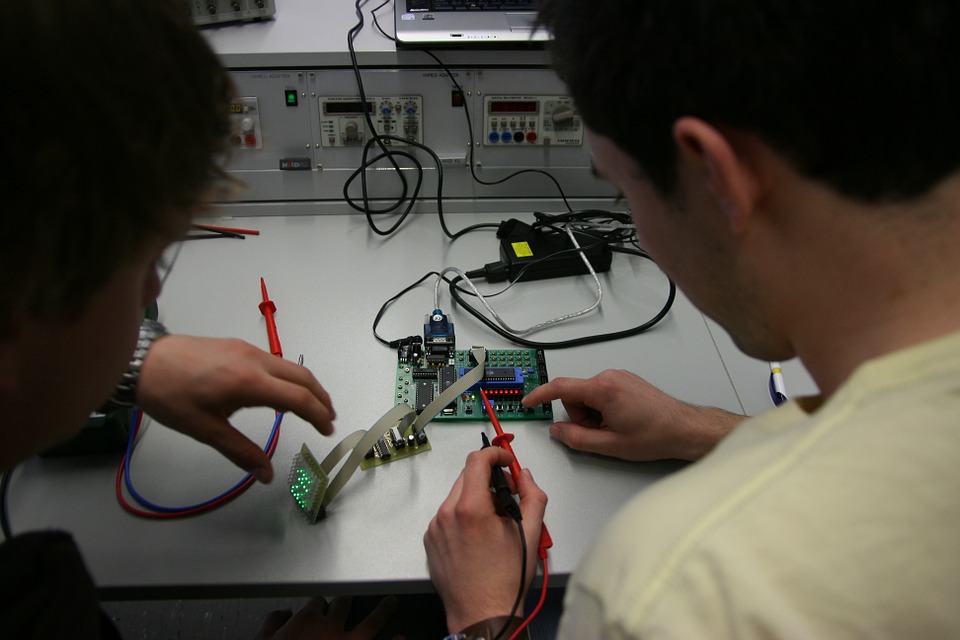

For the sake of determining the quality of your boards, manual visual inspection is one of the simplest methods that you can consider to use. Simple observation is needed in this method. A worker can make use of naked eyes of else magnification to carry out the observation. If you are considering to get accurate outcomes, you need to hire a worker with a high level of experience in making use of this specific inspection. A worker with a high experience level is capable of checking the common defaults. Of the several inspections that will be carried out here involve making sure that the firmness is okay, checking the quality of the surface, in addition to making sure that the thickness of the board is correct.

Automated optical inspection is another method that you can consider to help you check the quality of the PCB. Typically, this method happens to be complicated. This is because it uses cameras that are put at various angles so that they can reveal the exact PCB condition. Luckily, this method can reveal varying defects that might have been hard to reveal through the observation method. Also, the process is fast, as well as reliable.

On the other hand, you can carry out the PCB inspection through the X-Ray inspection. This method happens to use x-rays to reveal defects in the PCB. The major reason why this method was devised is that professionals in the industry realized that technology was advancing and it was challenging to determine defects. Once this method was introduced, the issue was solved.