The Perfboard, (also known as a PCB Prototype Board), is a prototype circuit electronic material.

A rigid and thin sheet with holes at 0.1-inch intervals that is pre-drilled on a square grid.

Ringed by copper pads that are made of copper that is either square or round. But the naked board can also be supplied.

The cheaper Perfboard comes with pads only on the one side whereas the more expensive board comes with them on both sides (Plate-through holes).

As each of these holes are isolated electrically, the builder uses mini point-to-point wiring or wire wrap techniques to complete the circuit he is creating.

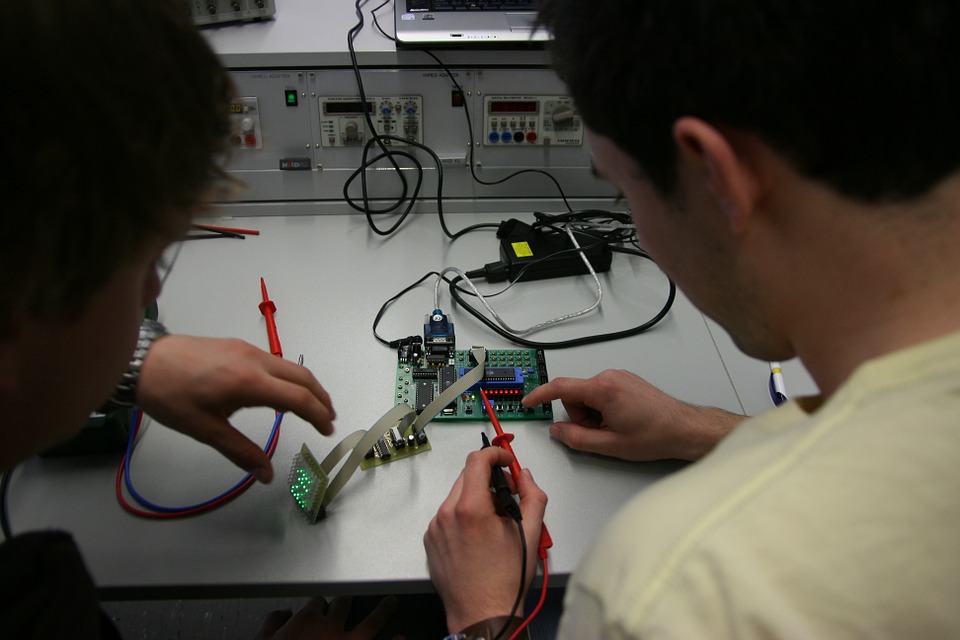

Small or tiny components are soldered onto these boards and examples of these components are integrated circuits, resistors, and capacitors.

Paper that is laminated with phenolic resin or a fiberglass-reinforced laminate epoxy is used to make the substrate.

These two are also known as FR-2 and FR-4.

Surface-mounted device prototypes are not used on these Perfboards as they are not designed for it, but rather through holes components like the DIP packages for integrated circuits on the grid systems 0.1-inch holes.

The connection and component locations are planned in detail on paper or by the use of software, which is to be placed on the Perfboard, before building a circuit.

There is quite a bit of software available for this mapping of the PCB layouts on the Perfboards.

The designer will position all the components so that the leads will be on the intersections of the 0.1″ grid.

Multi-overlaps is not a problem for insulated wires when routing connections that have 2 or more copper layers.

The components are soldered into each location once the layout is finalized, but keeping in mind integrated circuits, capacitors, diodes, and electrolytic capacitors have polarized parts so attention to orientation has to pay attention to.

As per the layout, the electrical connections are made. And so it goes until all components are connected and the circuit board is complete and ready for either combining with other circuit boards or added to bigger boards as per the use of the board created.

One last thought to mention, is you get another type of board called a stripboard which differs from the Perfboard:

Differences:

•The pads are individually isolated on a Perfboard

•Stripboards copper components are made in rows

•These connections are the default form on Stripboards

•Stripboards connections are broken down into isolated sectors

•Stripboards also require abrading throughout the copper

•Stripboards are more similar to the Breadboard’s solderless

pattern

•As the PCB Prototype Board has no default connectivity, the component positioning gives the designer freedom to do what can’t be done on Stripboards