Performing biomedical device testing is critical for public health and safety. Testing ensures the quality and effectiveness of medical equipment used in hospitals and medical centers. Testing also helps physicians obtain more accurate medical measurements. Biomedical device testing has several important components. For example, it can include End-to-end performance verifications and Medical error measurements.

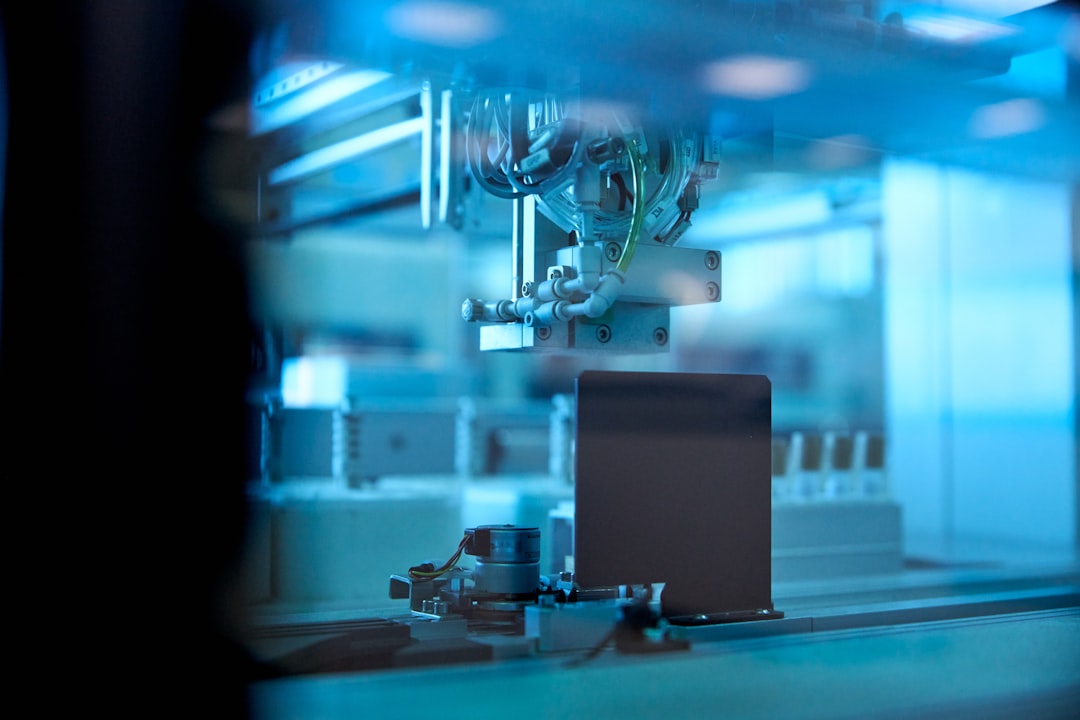

Laboratory testing is important for biomedical device testing:

Biomedical device testing is an essential part of the quality assurance process for medical devices. The testing profile of each device will vary depending on the materials it is made from and how it will be used. It is, therefore, important for manufacturers to understand their testing needs and ensure their devices meet them. Laboratory testing companies invest in the necessary testing equipment to perform these tests.

Testing labs can also provide validation of test methods, which is important for biomedical device manufacturers. Testing is also required to demonstrate that medical devices are safe for patients. As such, manufacturers must evaluate their testing methods and analyses and keep records of them. Tentamus’ laboratory network offers a comprehensive range of accredited testing services for medical devices. The laboratories perform testing in accordance with ISO 17025, US FDA, and other international standards. They also offer a range of services that meet the requirements of the European Medical Device Regulation.

End-to-end performance verifications

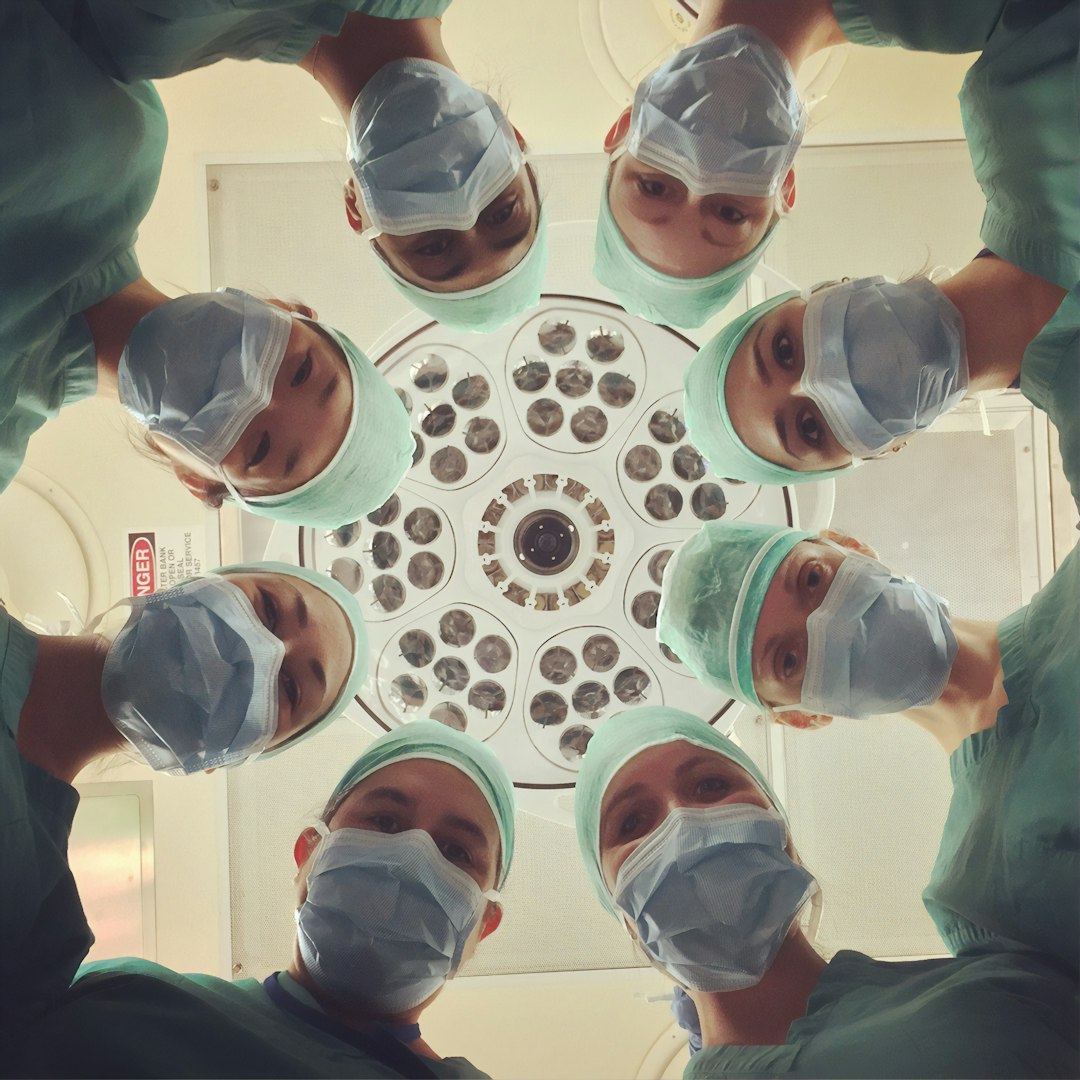

End-to-end performance verifications for medical devices are important to ensure that a device’s features are reliable. There are several types of these tests. One common process is the validation of sensor performance. This process involves evaluating the quality of sensors, including sensitivity and accuracy. During validation, an external third party will test the device. It is considered a gold-standard process.

End-to-end performance verifications for BioMeTs are performed before the devices are used on human subjects. This step ensures that the sample-level data obtained by sensors meets specified criteria and is not contaminated. This step also provides quality control in the data supply chain.

Medical error measurements

Medical error measurements are important in biomedical device testing to ensure that the device will function correctly in a patient. These measurements should take into account factors such as the operating environment, the patient’s ability to use the device, the user’s stress level, and the design of the device. These measurements also include a discussion of human factors in the context of human factors design.

These measurements can reduce the risk of critical errors caused by biomedical equipment. These errors can cause wrong diagnoses, medical device failure, or even patient death. It is, therefore, vital that biomedical equipment be regularly calibrated to ensure accurate measurements that can be traced to national standards.